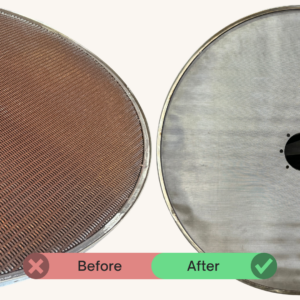

Re-Screening Pressure Leaves is Essential

At Steri, we understand the critical role that pressure leaf filters play in the chemical and pharmaceutical industries. Over time, Filter screens can become plugged and blinded, leading to decreased efficiency and increased operational costs. That’s why we offer comprehensive re-screening services for both our own pressure leaves and those of our competitors: Mavag Mavadisc, BHS, Schenk, Veolia, Sparkler, Durco, Amafilter, Leem and any other Pressure Leaf Filter brand.

- Maintain Optimal Flow Rates: A clogged screen can significantly reduce flow rates, impacting your production processes. Regular re-screening ensures that your filters operate at peak performance.

- Prevent Increased Pressure Differential (PSID): As screens accumulate debris and contaminants, the pressure differential across the filter increases. This can lead to operational inefficiencies and potential equipment damage.

- Extend Screen Longevity: The lifespan of a screen is influenced by the specific application and the number of cycles it undergoes. We recommend changing screens every 200 cycles to maintain optimal performance and prevent unexpected downtime.

- Minimize Downtime in Process: Routine re-screening helps prevent production downtime and product loss by ensuring that pressure leaf screen are maintained in optimal condition.